Stainless Steel Hopper Spreader

- Capacity: 1.5, 2.0, 3.0, 4.5 & 6.0 cu yd

- Material: Salt & Sand

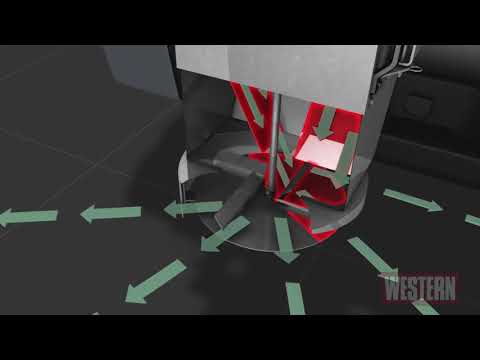

- Spread Pattern: Broadcast

MINIMIZE WASTE, MAXIMIZE PROFITS

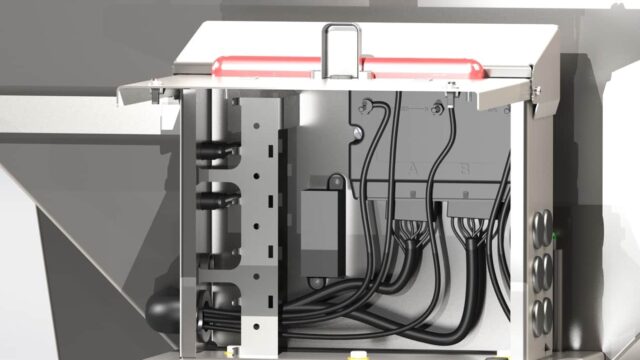

Minimize waste and maximize profits with the WESTERN® Striker® stainless steel hopper spreader. A dual variable-speed control and an innovative chute design allow operators to easily control salt and sand spread. Ultra-durable and loaded with the latest in snow and ice control technology, the Striker hopper spreader helps you take your de-icing operation further.

Featured Accessories

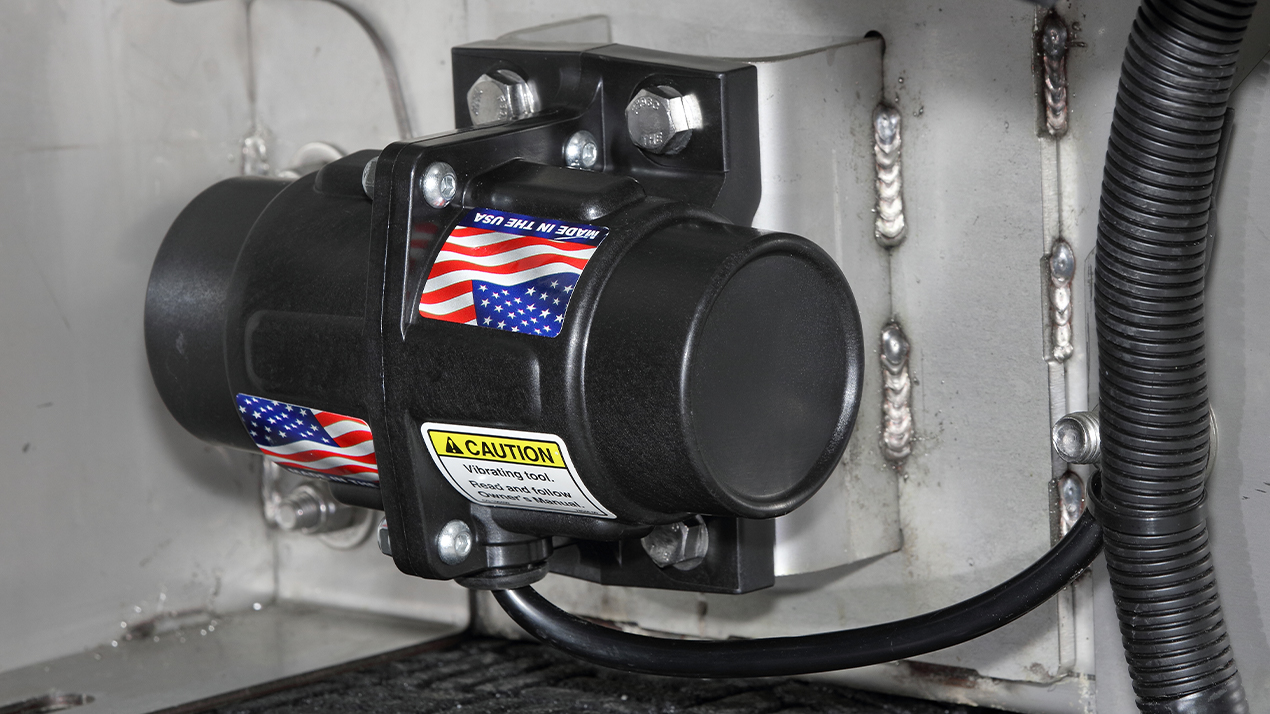

VIBRATOR KIT

Loosen up stubborn materials and prevent bridging with this Vibrator Kit. Featuring a 200V DC vibrator motor in a metal housing, our vibrator will help prevent bridging and clogging, improving material flow so you can do your job faster and better.

Part Number

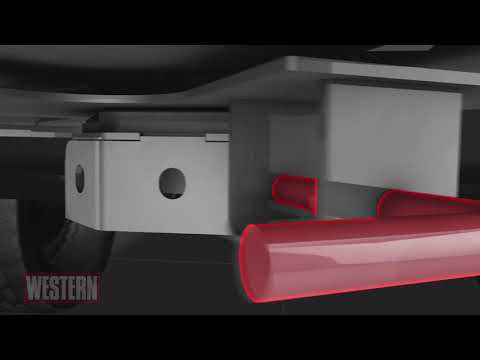

6" SIDE EXTENSIONS

Hold more material in your Striker® stainless steel hopper spreader with these 6″ extension kits. Each kit contains the brackets needed to add up to one additional yard of capacity depending on the hopper size (wooden boards not included).

Part Number

Product Specs

| Models | 1.5 cu yd | 2.0 cu yd | 3.0 cu yd | 4.5 cu yd (9') | 4.5 cu yd (10') | 6.0 cu yd |

|---|---|---|---|---|---|---|

| Vehicle Compatibility | 3/4- & 1-Ton Pickup Trucks | 3/4- & 1-Ton Pickup Trucks | Dump Body or Flatbed Trucks (Over 15,000 lb GVWR) | Dump Body or Flatbed Trucks (Over 15,000 lb GVWR) | Dump Body or Flatbed Trucks (Over 15,000 lb GVWR) | Dump Body or Flatbed Trucks (Over 15,000 lb GVWR) |

| Vehicle Compatibility | 3/4- & 1-Ton Pickup Trucks | 3/4- & 1-Ton Pickup Trucks | Dump Body or Flatbed Trucks (Over 15,000 lb GVWR) | Dump Body or Flatbed Trucks (Over 15,000 lb GVWR) | Dump Body or Flatbed Trucks (Over 15,000 lb GVWR) | Dump Body or Flatbed Trucks (Over 15,000 lb GVWR) |

| Material Compatibility | Bulk Salt, 50/50 Salt/Sand Mix, Sand | Bulk Salt, 50/50 Salt/Sand Mix, Sand | Bulk Salt, 50/50 Salt/Sand Mix, Sand | Bulk Salt, 50/50 Salt/Sand Mix, Sand | Bulk Salt, 50/50 Salt/Sand Mix, Sand | Bulk Salt, 50/50 Salt/Sand Mix, Sand |

| Material Compatibility | Bulk Salt, 50/50 Salt/Sand Mix, Sand | Bulk Salt, 50/50 Salt/Sand Mix, Sand | Bulk Salt, 50/50 Salt/Sand Mix, Sand | Bulk Salt, 50/50 Salt/Sand Mix, Sand | Bulk Salt, 50/50 Salt/Sand Mix, Sand | Bulk Salt, 50/50 Salt/Sand Mix, Sand |

| Capacity | 1.5 cu yd | 2.0 cu yd | 3.0 cu yd | 4.5 cu yd | 4.5 cu yd | 6.0 cu yd |

| Capacity | 1.15 cu m | 1.53 cu m | 2.29 cu m | 3.44 cu m | 3.44 cu m | 4.59 cu m |

| Spreading Width | Up to 40' | Up to 40' | Up to 40' | Up to 40' | Up to 40' | Up to 40' |

| Spreading Width | Up to 12.19 m | Up to 12.19 m | Up to 12.19 m | Up to 12.19 m | Up to 12.19 m | Up to 12.19 m |

| Approx. Weight (Empty) | Dual 12V DC Sealed Motors (595 lb) | Dual 12V DC Sealed Motors (615 lb) Dual Hydraulic Motors (615 lb) | Dual 12V DC Sealed Motors (695 lb) Dual Hydraulic Motors (695 lb) | Dual 12V DC Sealed Motors (815 lb) Dual Hydraulic Motors (815 lb) | Dual Hydraulic Motors (840 lb) | Dual Hydraulic Motors (885 lb) |

| Approx. Weight (Empty) | Dual 12V DC Sealed Motors (269.89 kg) | Dual 12V DC Sealed Motors (278.96 kg) Dual Hydraulic Motors (278.96 kg) | Dual 12V DC Sealed Motors (315.25 kg) Dual Hydraulic Motors (315.25 kg) | Dual 12V DC Sealed Motors (369.68 kg) Dual Hydraulic Motors (369.68 kg) | Dual Hydraulic Motors (381.02 kg) | Dual Hydraulic Motors (401.43 kg) |

| Overall Dimensions (LxWxH) | 105" x 50" x 51" | 117" x 50" x 51" | 129" x 50" x 70 ½" | 129" x 70" x 74 ¾" | 141" x 70" x 74 ¾" | 141" x 70" x 82 ¼" |

| Overall Dimensions (LxWxH) | 266.7 cm x 127 cm x 129.5 cm | 297.2 cm x 127 cm x 129.5 cm | 327.7 cm x 127 cm x 179.1 cm | 327.7 cm x 177.8 cm x 189.9 cm | 358.1 cm x 177.8 cm x 189.9 cm | 358.1 cm x 177.8 cm x 208.9 cm |

| Hopper Dimensions (LxWxH) | 84" x 50" x 33.25" | 96" x 50" x 33.25" | 108" x 50" x 40.75" | 108" x 70" x 45" | 119" x 70" x 45" | 119" x 70" x 52.5" |

| Hopper Dimensions (LxWxH) | 213.4 cm x 127 cm x 84.5 cm | 243.8 cm x 127 cm x 84.5 cm | 274.3 cm x 127 cm x 103.5 cm | 274.3 cm x 177.8 cm x 114.3 cm | 302.3 cm x 177.8 cm x 114.3 cm | 302.3 cm x 177.8 cm x 133.4 cm |

| Body Side Length | 7' | 8' | 9' | 9' | 10' | 10' |

| Body Side Length | 2.13 m | 2.44 m | 2.74 m | 2.74 m | 3.05 m | 3.05 m |

| Min. Bed Length | 62.5" | 74.5" | 91" | 91" | 102" | 102" |

| Min. Bed Length | 158.8 cm | 189.2 cm | 231.1 cm | 231.1 cm | 259.1 cm | 259.1 cm |

| Conveyor Width | 16.5" | 16.5" | 16.5" | 16.5" | 16.5" | 16.5" |

| Conveyor Width | 42 cm | 42 cm | 42 cm | 42 cm | 42 cm | 42 cm |

| Spinner Size | 15.5" | 15.5" | 15.5" | 15.5" | 15.5" | 15.5" |

| Spinner Size | 40 cm | 40 cm | 40 cm | 40 cm | 40 cm | 40 cm |

| Hopper Construction | 16 ga SS | 16 ga SS | 16 ga SS | 16 ga SS | 16 ga SS | 16 ga SS |

| Hopper Construction | 1.5 mm SS | 1.5 mm SS | 1.5 mm SS | 1.5 mm SS | 1.5 mm SS | 1.5 mm SS |

Product Literature

Spreader Selector Tool

Does This Spreader Fit My Vehicle?